HELLO AND WELCOME

Brunehaut Brewery

ORGANIC INGREDIENTS

PROMOTING SUSTAINABLE DEVELOPMENT

OUR LOCAL PRODUCERS

SOLAR ENERGY

Story

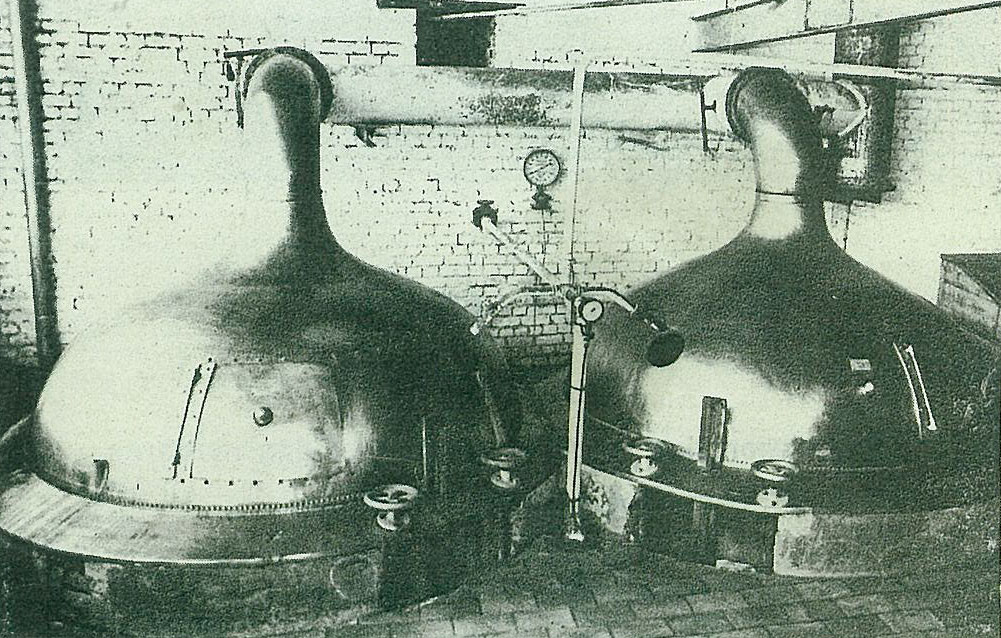

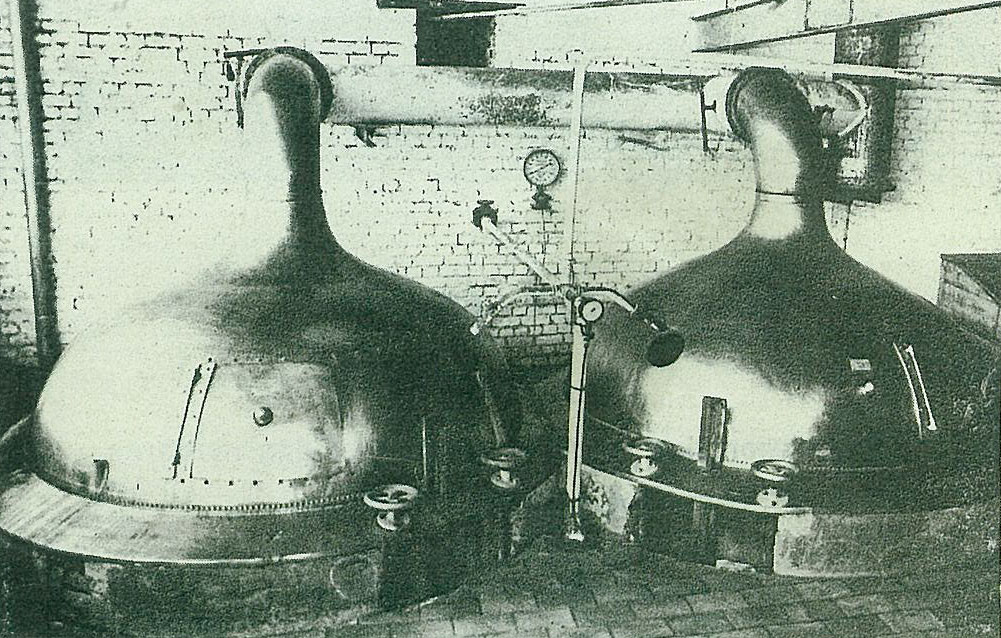

Founded in 1890, the Brasserie Brunehaut (brewery) blends tradition and modernity.

A century later, the brewhouse moved 2km (1.24mi) from the original site, remaining on the same water table with the same pristine water quality.

When a 2007 acquisition changed ownership, annual brewery production stood at 1000 hectoliters. Today, total brewery output has more than quintupled.

Nevertheless, Brunehaut remains an artisanal brewery, strong in its rich history and modern values.

Our commitment to the Future

- We produce the best organic and gluten-free craft beers, without compromise.

- We increase sustainability at every opportunity, to maximize positive impact on our human and natural resources.

- We continuously re-invest in the well-being of our employees and quality of our beer.

- We communicate our values to our customers, suppliers and vendors.

- We are part of a positive spiral with respect for Man and Nature.

- We use money as a means, not an end.

Cheers !

OUR TEAM

TEAM BRUNEHAUT

B-corp

Our Brunehaut brewery, which annually brews 6,000 hectoliters of organic beer, has become the European Community's first B Corp certified brewery.

Already labeled Bio (Organic), Nature & Progrès and Prix Juste Producteur, we produce the only official organic Belgian Abbey beer (Abbaye de Saint Martin) plus the premier, gluten-free Brunehaut Organic labels.

- The world's first brewer to distribute recyclable export kegs,

- our 350 rooftop solar panels produce 75% of required brewing electricity.

- A water consumption reduction initiative is also underway.

- Our output is 100% organic.

- Brunehaut gluten-free beers are recognized as the world's best.

- We source ingredients as locally as possible and pay our farmers at accepted fair-trade levels.

- Our production investments are motivated first by employee well-being.

- "Partner" collaborations are made with companies who share our circular economy principles. (Sturm, Houblonde, La Miche, etc.)

OUR SECRET METHODS FOR

BREWING ORGANIC BEER

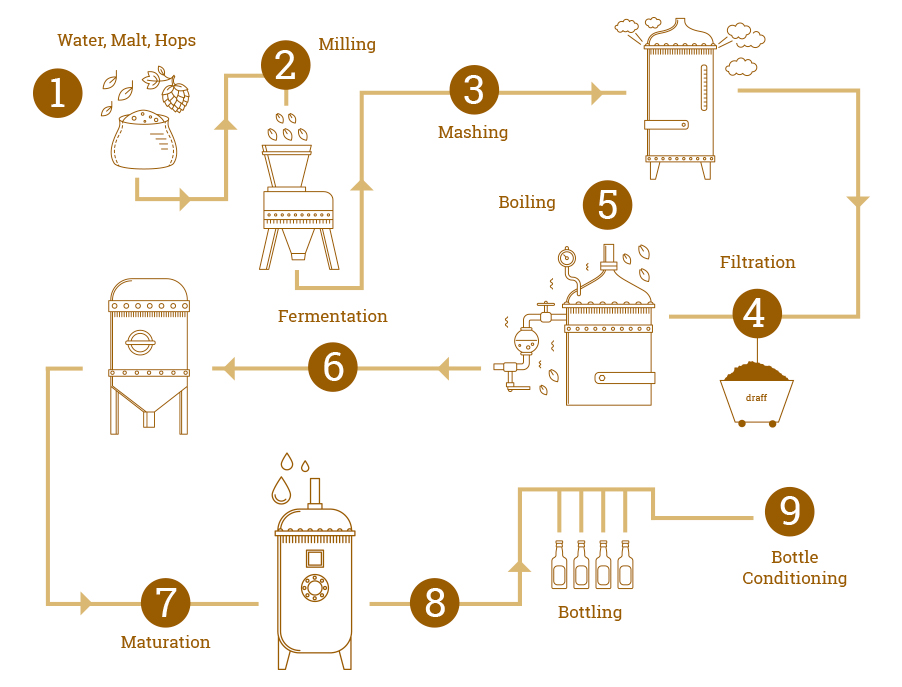

Water, Malt, Hops

The brewer carefully selector 100% natural ingredients, from local farms. This is an essential condition for premium brewing.

Milling

Barley, malt and other grains are ground into a coarse flour.

Mashing

The flour is next mixed with water and precisely heated. At this stage, the heat transforms the brewing flour into a “mash” as barley enzymes turn starch to sugar.

Filtration

Next, our brewing mash is filtered and separated into liquid and solid components. The liquid, which becomes beer, is called wort. The solid, known as draff, is a brewing byproduct eventually reused for other non-brewing purposes, often as animal food.

Boiling

The must is brought to a boil. During and after boiling hops and spices will be added to infuse in the must.

Fermentation

Our cooled must is next transferred, with yeast, to a fermentation tank. For ten days, the yeast transforms all the sugar into alcohol, CO2 and esthers.

Maturation

After fermentation, the beer temperature is next brought to 0°C for a minimum of ten days. This guarantees maturation of the beer which is also refined and clarified.

Bottling

Next, after light filtration, comes bottling. Brunehaut beers are bottled in 33cl and 75cl bottles plus 20 liter recyclable kegs.

Bottle Conditioning

Beer foam and bubbles are produced naturally by in-the-bottle fermentation. This a process is equivalent to the “secondary” Champagne method.

THE ALLIANCE OF

TRADITION AND MODERNITY

News

DISTRIBUTION

WHERE TO FIND OUR BEERS ?

Europe

Austria

www.abaco-trade.at

Croatia

www.biomania.hr

Denmark

www.detbelgiskehus.dk

Spain

www.singletaste.es

Estonia

www.scandinaviawine.com

Finland

www.redbev.fi

France

www.azade.fr

www.sturmbio.com

www.lacentraledesbieres.fr

Britain

vinceremos.co.uk

vintageroots.co.uk

Greece

irini@massokostasbros.gr

Italy

www.birrabelga.eu

Iceland

asgeir@mannberg.is

Malta

coregreen.eu

Norway

www.selectedwinepartners.no

Netherlands

www.multibier.nl

Poland

www.smakpiwa.pl

Russia

www.new.bairos.ru

Sweden

www.concealedwines.se

Swiss

www.naturalex.ch

Europe and Wallonia: committed and responsible in your region

The purchase of a beer bottling machine (5,000 bottles/hour) is co-funded by the European Union as part of the European Agricultural Fund for Rural Development (EAFRD).